10 ways in 2021 to reduce costs direct to your bottom line

2020 was hard. 2021 might well be harder! The reality of delaying your 2020 plans and pushing things out to a brighter day can no longer be ignored. We are entering a period of the new normal!

You need to take action and reduce your costs now.

Cost savings in a business can be made in a number of areas. The key aims of a procurement supported saving initiative(s) are to drive down operating costs, without impacting quality, while reducing business risk and improving supplier performance. AN added bonus is to collaborate internally and build relationships and trust by delivering great outcomes for the business.

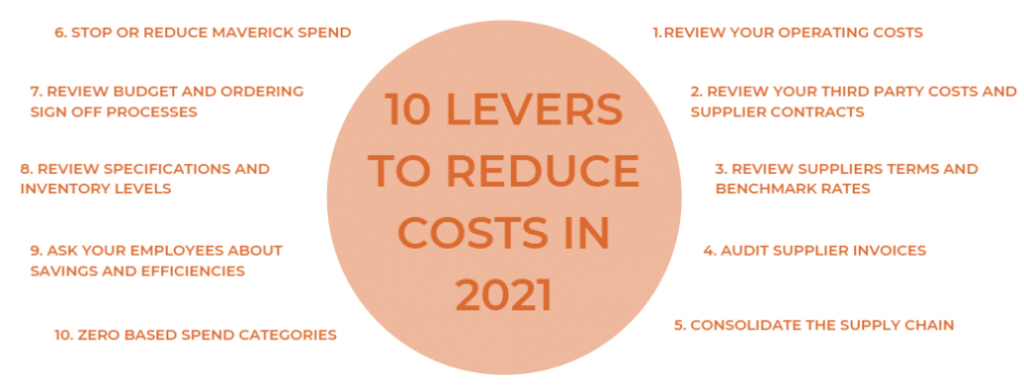

The below is a basic top 10 list of levers to help you reduce costs fast…

1.Review your operating costs

Extract and review all operating spend data from the last 12 months. Both employee costs and third-party costs (for the latter ideally 24 months to compare and identify trends). Typically, your two biggest expenditures will be people and property. If you desperately need to make financial decisions, you will need to review these; cost modelling employee costs against your revenue, growth and make vs buy (manage yourselves or outsource) and reviewing your property portfolio for opportunity to reduce or release fixed monthly costs.

Although this is the first step, and you will equally want to review your revenue streams, we strongly recommend finding ways to deliver value fast to the P&L (we do that by applying 36 key efficient qualification criteria to each spend area to quickly identify where the savings are)

The remaining 9 options focus on third party costs, areas which can be delivered relatively quickly with minimal disruption – and which you should manage continuously…

2. Review your third party spend and contract data

Extract and review all supplier spend data from the last 12/24 months. Usually this will be purchase order data rather than invoice data, to enable you to review the detail, then cleanse and categorise accurately. Remember to include purchasing card and expenses data often captured and held separately.

Once categorised, review the spend data by supplier against signed contracts to identify gaps in compliance and risk.

For the purpose of this blog, I have over-simplified this part of the procurement process, so focus on high and/or key repeatable spend, and areas for opportunity to avoid or reduce costs and improve efficiencies, whether via consolidation, rate reduction or contract negotiation.

3. Review supplier’s terms & benchmark rates

Ensure that an appropriate contract and process exists for all suppliers, especially key suppliers. Benchmark key supplier rates against the market. Such benchmarking reviews will usually identify areas of opportunity in any contract, whether via improvement in incumbent terms/rates or competitive change of supplier (accessing current and accurate benchmark data can be challenging. We source over £0.5bn per annum of goods and services so have access to current pricing for many spend areas so you may want to talk to an external expert). Remember to collaborate with your supply chain for win/win opportunities – simply demanding greater discounts without ensuring your supplier can maintain services could create risk and animosity. Suppliers must be allowed to make a sensible level of profit.

4. Audit supplier invoices

Check that key and repeatable supplier invoicing is accurate i.e. discounts, rebates and prebates have been applied correctly) and that KPIs/SLAs have been achieved. There may be potential for immediate bottom line cashflow boost here – but be careful, if found, and even if contractually due, you may need to liaise with your suppliers for a payment plan (especially this year) to avoid crippling your partner.

5. Consolidate the supply chain

When undertaking a review of your annual spend and supplier terms, this will identify opportunities to consolidate categories/suppliers and immediately (except for contract restrictions) leverage volumes for improved rates and terms with third parties. This could also realise additional cost savings from process efficiencies such as reduced administration in ordering, invoicing and supplier management.

6. Stop or reduce maverick spend

Typically any spend outside of preferred suppliers – often known as maverick or rogue spend – can account for up to 80% of the supply chain. By identifying and categorising this tail of spend by repeatable and project spend, it is always possible to identify opportunities to save money fast (via consolidation, negotiation and even stopping non-required spend altogether).

7. Review budget and ordering sign off processes

Enhancing budget and approval processes will support you ensure only strictly necessary purchases are being made, cutting down on excess costs, storage costs and administrative costs.

8. Review specifications and inventory levels

Review the specifications, with key business owners, of key and repeatable goods and services being purchased – can a lesser specification at a lower price still achieve the same outcome? (aim to embed this thinking culturally across the business ongoing)

Can your operation function with lower stock levels to reduce admin, wastage and storage costs?

9. Ask your employees about savings and efficiencies

Conduct a short and efficient survey to ask your employees where savings could be achieved. They will likely identify areas you may not have considered, and such buy-in/engagement can work wonders for helping deliver the savings quickly (and maintaining a culture of savings identification and delivery, and process efficiency thereafter). Be careful that you create the right positive engagement to such a survey that benefits both the business and individuals.

10. Zero based spend categories

This one is more drastic. During your review, if any spend category is not fulfilling a key purpose or delivering an outcome, should you stop it altogether? You will often see budget reductions at difficult times for areas like marketing and training, but have you considered usually key or protected areas.

Of course, this list is not an exhaustive list of all the options (short term tactical or longer term strategic) – but hopefully is a quick helping guide for what to consider as you start a challenging 2021!

If you are already more advanced in your cost review process, you may want to consider deeper dives into your purchase to pay (P2P) systems and processes (such as expenses processes), technology (such as unnecessary or downgraded licenses and systems), price tracking due to Covid and Brexit cost volatility in areas such as food, insurance, energy etc.

Strategically, do not forget the need to cover your Cyber policies, supplier risk management and social value initiatives – all key topics going into 2021!

Marr Procurement is working with multiple clients, in private and public sectors, across multiple sectors such as Care, Social Housing, Charity, Maritime, Logistics and Industrial at the start of 2021 on similar cost saving and process improvement initiatives.

If your organisation could benefit from external support on Procurement, Operational or Transformational activities please get in touch. We would be happy to discuss them without cost or obligation to you.

Contact us TODAY to see if you may qualify for a free savings review

Article written by James Ball, Marr Procurement Director who can be contacted on james.ball@marrprocurement.com